Production

Milling

We specialize in custom, small-batch, as well as serial production of parts with various degrees of difficulty in manufacturability. Due to the variety of products, we have adapted our machine park to meet the shortest delivery dates and the most favorable price of parts. Currently, we have seven milling machining centers, including a 5-axis Pinnacle BX900T center with a tilting spindle, a built-in rotary table dia. 800 mm and with the possibility of turning. For the production of complex 3D parts, another 5-axis HAAS center with internal spindle cooling and the possibility to machine a part with dimensions of 650 x 500 x 300 mm helps us. Another point of interest is the 4-axis Fanuc-Robodrill center, which is primarily intended for serial orders. An integral part of our park are two Datron machines used mainly for productive machining of soft metals and plastics with the help of vacuum clamping of workpieces - max. the dimensions of the semi-finished product are 1500 x 1000 x 30 mm.

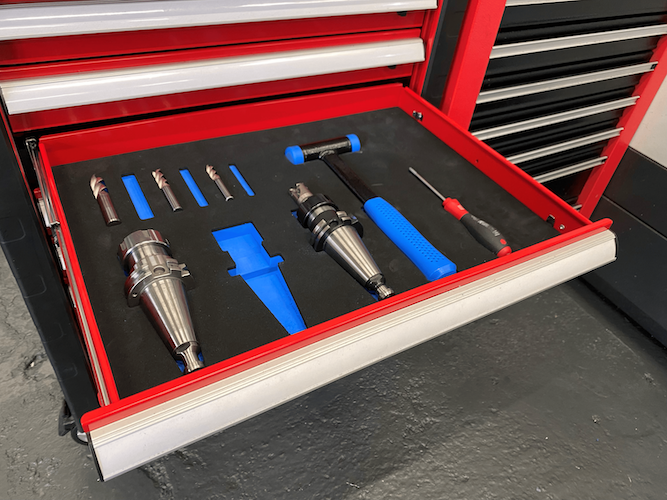

Milling of foam fillings

Thanks to Datron machines, we can also produce filling foams for suitcases, drawers and foam-like applications. The remaining two machines are 3-axis Leadwell CNC centers used mainly for milling difficult-to-machine materials for series, small-series and custom production. Programming of parts takes place exclusively with the help of CAM software Edgecam, and editing of 3D models is carried out in SolidWorks software.